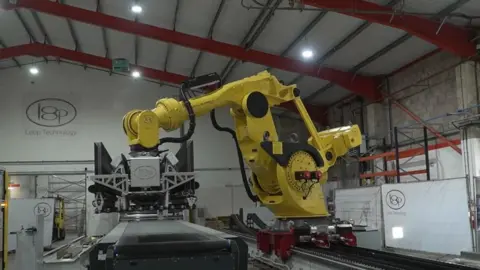

Gigantic robots at work at King's development

One of the largest industrial robots in the UK is currently operating at the King's Poundbury development in Dorset.

The gigantic FANUC M-2000iA 1700L is the strongest long-reach robot in the world, and is being used by automation and robotics specialists Loop Technology.

It is part of the company's automated set up, which shapes pieces out of carbon fibre for use in aircraft wings.

Managing director Alun Reece called the robot "amazing" and told the BBC: "The irony is you've got this big automation to make lightweight structures."

Loop Technology was founded in 1998, starting with a single robot in a living room.

It said its manufacturing work was part of a worldwide focus to build lighter, more fuel-efficient and sustainable aircraft, contributing to net zero targets.

Mr Reece said part of the solution was to make wings "more aerodynamic and more efficient with less drag - the overall fuel burden on the aircraft is lower".

In all the company ordered seven FANUC robots. Each one can easily lift and position the equivalent of an entire car body.

The company has fitted them with a specialised gripper - itself weighing a tonne - which can pick up and manipulate sheets of carbon fibre.

Carbon fibre weighs less than traditional materials used in aircraft building, and is also stronger, helping to reduce the carbon footprint of plane travel.

The cutting system, and the tracks the robots use, are also the largest of their kind.

"They want to make these aircraft at phenomenal rates, somewhere between 80 and 100 planes a month," Mr Reece said.

"So that's a lot of material that has to go in a mold very quickly.

"This can do in 35 seconds what it would take traditional techniques a couple of hours to do."

Mr Reece described the setting of Poundbury as "almost like a Victorian film set".

Construction on the experimental town on the edge of Dorchester, began in 1993 on architectural principles championed by the then Prince Charles.

By the time of its completion in 2028, the Duchy of Cornwall community is expected to have grown to 2,740 homes, according to Buckingham Palace.

Mr Reece added: "We don't have to live in the city. We have the luxury of living more or less in the countryside, by the sea, on a beach.

"What's not to like? It's kind of in a way living the dream."

You can follow BBC Dorset on Facebook, X (Twitter), or Instagram.